That has inspired us, guided us, protected us. That has given us values to follow, ideas in which to believe, projects to share. That has given us a family and people on which we can count; researchers, farmers, customers so we can continue to evolve and improve. Nature has taught us all of the things that you can find in our products.

BECAUSE A BETTER FUTURE FOR US IS A BETTER FUTURE FOR EVERYONE.

We work every day to construct a virtuous path towards environmental sustainability, firmly convinced that only by pursuing sensitive environmental policies can we secure ourselves a better future, a future in which nature and all of its precious biodiversity is still able to flourish..

For us sustainability is safeguarding the planet, taking account of the delicate equilibrium of the ecosystem and respecting the people that work on the land.

CLEAN AND RENEWABLE ENERGY

We use exclusively 100% clean electricity for all our working activities and for some of our production operations. 100% of the energy we use comes from renewable sources with a significant reduction in the quantity of oil used and the amount of carbon dioxide emitted into the environment. In 2021 alone we saved 2244 tonnes of oil (13,460 barrels) and avoided the emission of around 6400 tonnes of CO2 into the atmosphere.

A sustainability project that involves the introduction of geothermal plants in our warehouses, a system capable of exploiting the resources and natural warmth of the subsoil for the heating and cooling of the buildings.

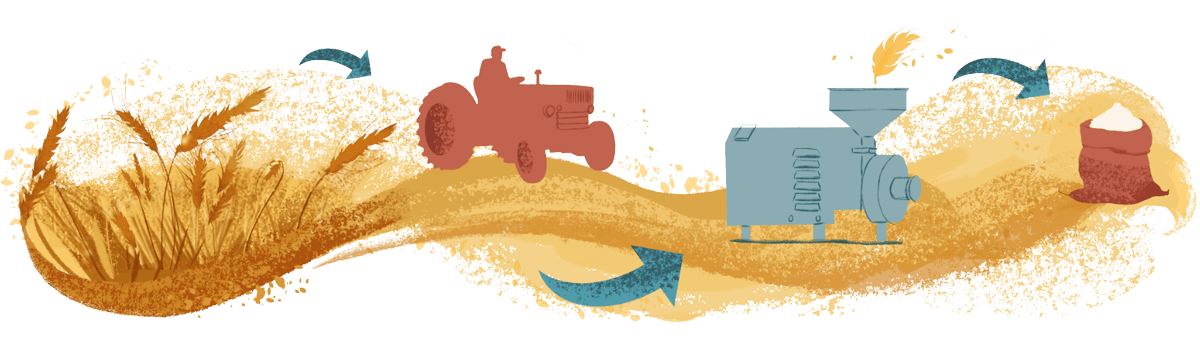

CONTROLLED SUPPLY CHAIN PROJECTS

FSC CERTIFIED PAPER

We use FSC® certified paper, deriving from responsibly managed forests and completely recyclable, to package the majority of our products.

WE SUPPORT THE CIRCULAR ECONOMY

We use all parts of the grain; in fact, even the parts not suitable for human consumption are used in production chains like the livestock supply chain.

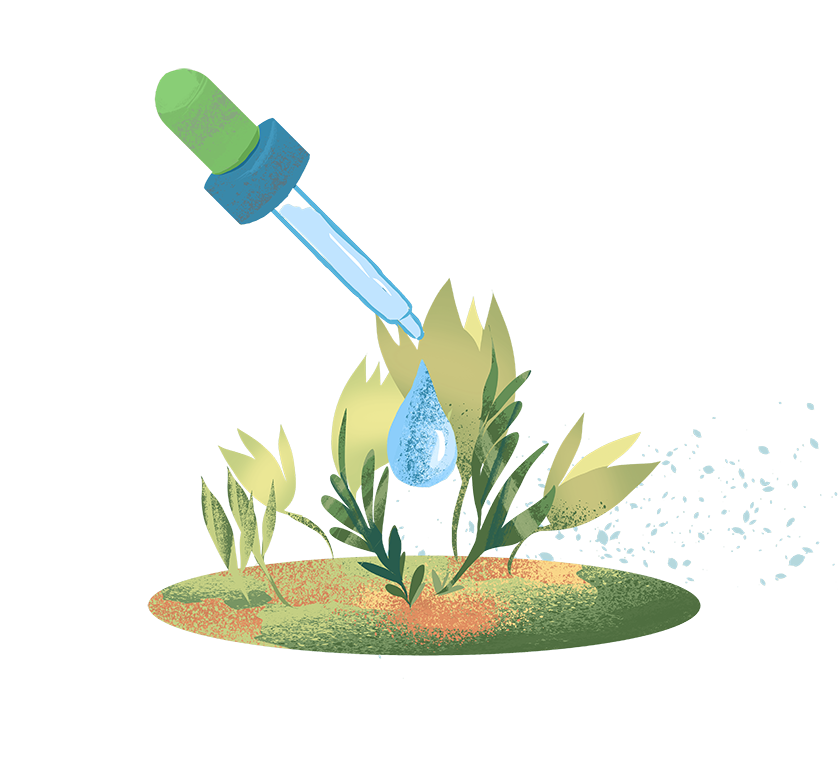

WE ONLY USE THE WATER WE NEED

Thanks to MYFA technology

We save water, using only what we need. The water we use for the milling process is essential for wetting the grain so it can be broken by the roller mills. However, thanks to MYFA technology we are able to avoid wasting water as only the amount strictly required for the grain to reach the ideal level of humidity is withdrawn; only the total amount of water that will be used in the process is withdrawn meaning that once the process is completed the production department does not have any industrial water to discharge.

WASTE COMPACTION

We help reduce the consumption of resources thanks to the introduction of a compaction system in the waste cycle which makes it possible to use end-of-life products to make raw materials to use in the production processes, reducing the transport of materials and, as a consequence, also CO2 emissions.